DATA CENTERS

Thermodynamic Optimization: Improving WUE Metrics in Legacy Data Center Infrastructure

A deep dive into retrofitting adiabatic cooling systems and optimizing Cycles of Concentration (CoC) to meet modern Water Usage Effectiveness standards without complete plant capitalization.

The metric is simple: liters per kilowatt-hour (L/kWh). But achieving a Water Usage Effectiveness (WUE) of < 0.2 in a facility built in 2010 is a challenge of thermodynamic complexity. While hyperscalers deploy direct-to-chip liquid cooling, legacy operators must squeeze efficiency from evaporation.

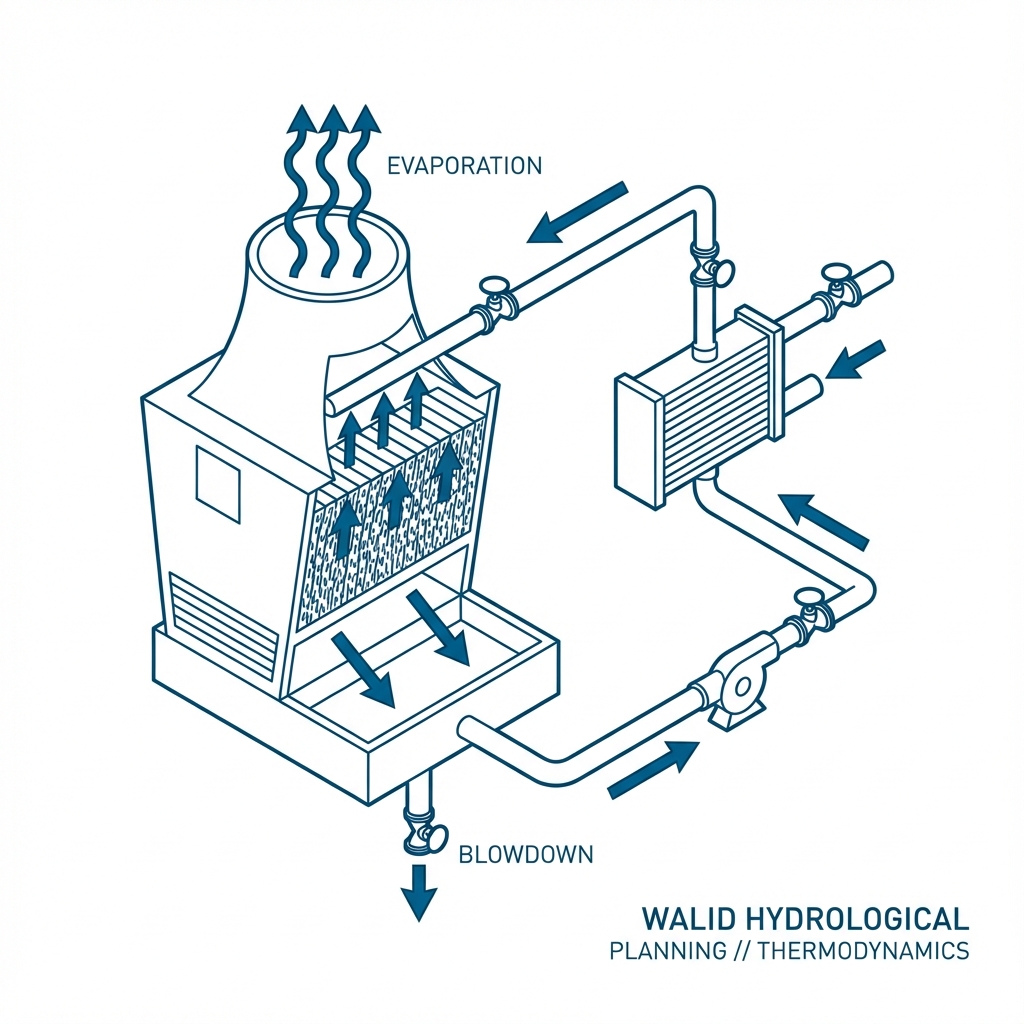

The Physics of Evaporative Rejection

Legacy data centers efficiently reject heat via the latent heat of vaporization of water ($h_{fg} \approx 2260 \text{ kJ/kg}$). This is thermodynamically superior to sensible heat transfer (air cooling) but inherently consumptive. For every ton-hour of cooling (12,000 BTU), a cooling tower theoretically evaporates ~1.8 gallons of water, assuming standard psychrometric conditions.

The problem arises not from evaporation - which is the "productive" use of water - but from Blowdown (or bleed). Blowdown is the water intentionally drained from the tower to prevent the concentration of dissolved solids (Calcium, Silica) from scaling the heat exchangers.

The Governing Equation of Water Efficiency

Total water consumption ($M_{makeup}$) is defined by the Cycles of Concentration (CoC):

Where:

- $M_{evaporation}$ is fixed by the cooling load (IT load).

- $CoC$ is the ratio of conductivity in the tower water to the makeup water.

The Math of Diminishing Returns:

- Moving from 2 Cycles to 4 Cycles cuts total water usage by 33%.

- Moving from 4 Cycles to 6 Cycles cuts it by only 6%.

For many legacy plants operating at a safe 2.5 Cycles, the "low hanging fruit" is pushing that number to 5.0 or 6.0.

Retrofit Strategy 1: Smart Conductivity Controllers & Acid Feed

Why do operators run at low cycles? Fear of scale. Calcium Carbonate ($CaCO_3$) precipitates rapidly as pH rises (which happens naturally as CO2 strips out in the tower). By installing automated mineral acid feed systems ($H_2SO_4$), we can suppress the alkalinity, keeping Calcium soluble at much higher concentrations. This allows safe operation at 6-8 Cycles, slashing blowdown waste.

Retrofit Strategy 2: Side-Stream Filtration

Suspended solids (dirt, biological growth) provide nucleation sites for scale formation. Implementing a side-stream sand or disk filter that turns over the tower basin volume every hour removes these solids, allowing the chemical program to be pushed harder without risk to the chillers.

The Adiabatic Advantage

For air-cooled chillers, adding adiabatic pre-cooling pads is a minimal CAPEX intervention. By spraying water into the airstream only when ambient dry bulb temperatures exceed 85°F, we shave the peak electrical demand. The WUE impact is minimal because water runs for only ~200 hours/year, but the PUE (Power Usage Effectiveness) reduction is significant.

Regulatory Pressure: 316(b) and Intake Limits

Facilities drawing from surface waters face Section 316(b) of the Clean Water Act, regulating impingement and entrainment of aquatic life at cooling water intake structures (CWIS). Reducing intake volume via higher CoC is often the most cost-effective way to comply with these biological performance standards without building expensive traveling screens.

Conclusion

Optimizing WUE in legacy facilities is an exercise in water chemistry control. It does not require replacing the cooling towers; it requires upgrading the brains (controllers) and kidneys (filtration) of the system. We target a range of 4.0 - 5.0 Cycles as the "Golden Ratio" for water efficiency versus chemical risk.

About the Author

Zayd Walid

Principal Consultant