COMPLIANCE

Understanding 2026 PFAS Compliance Requirements: A Technical Analysis of EPA Method 1633 and Treatment Train Engineering

A rigorous examination of the EPA's final MCLs for PFAS compounds, focusing on the transition to Method 1633 for compliance monitoring and the engineering challenges of implementing GAC versus Ion Exchange treatment trains in industrial effluents.

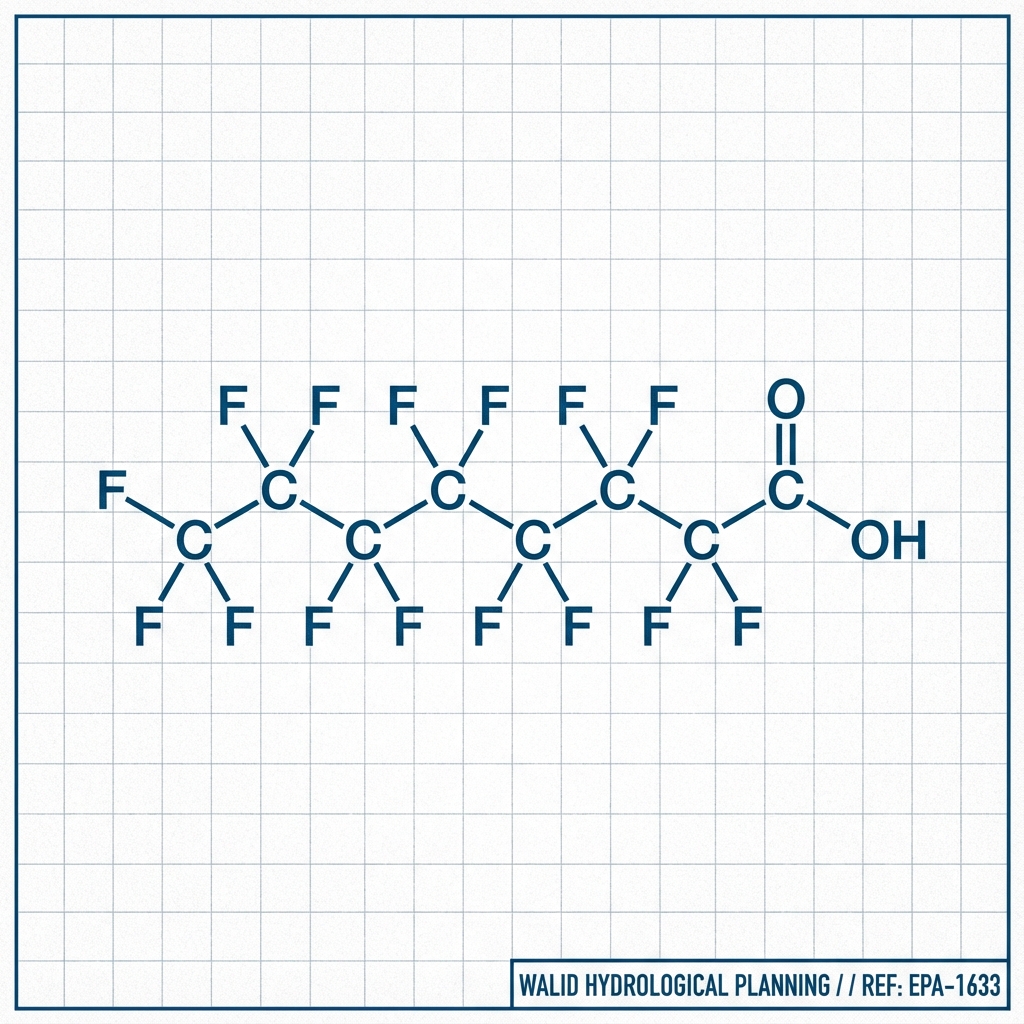

The regulatory landscape for industrial wastewater discharge has undergone a tectonic shift with the EPA's 2024 finalization of Maximum Contaminant Levels (MCLs) for per- and polyfluoroalkyl substances (PFAS). This is not merely a tightening of limits; it is a fundamental change in the chemistry of environmental compliance.

The Regulatory Paradigm Shift: From 537.1 to Method 1633

For the past decade, industrial dischargers relied on EPA Method 537.1 for drinking water compliance. However, the complexities of non-potable matrices - industrial wastewater, landfill leachate, and biosolids - demanded a more robust analytical protocol. Enter EPA Method 1633.

Method 1633 is the first EPA-validated method to test for 40 specific PFAS compounds in wastewater, surface water, groundwater, soil, biosolids, sediment, landfill leachate, and fish tissue. Unlike its predecessors, it utilizes isotopically labeled standards for quantitative determination, minimizing matrix interference.

Key Technical Differences

| Parameter | Method 537.1 (Legacy) | Method 1633 (Compliance Standard) |

|---|---|---|

| Target Analytes | 14-18 compounds | 40 compounds (including precursors) |

| Matrices | Drinking Water only | Wastewater, Soil, Tissue, Biosolids |

| Quantification | Internal Standard | Isotope Dilution (Gold Standard) |

Implication for Industry: Facilities monitoring their effluent with Method 537.1 are gathering legally defenseless data. For NPDES permit renewal applications in 2026, regulators will reject anything other than Method 1633. The detection limits are in the single-digit parts per trillion (ppt), meaning that cross-contamination during sampling (from LDPE tubing, waterproof notebooks, or even Gore-Tex clothing) can result in a false positive violation.

The PFOA/PFOS MCLs and "Superfund" Liability

The final Enforceable MCLs set a limit of 4.0 ppt for PFOA and PFOS individually. To contextualize this: 4.0 ppt is equivalent to four drops of water in an Olympic-sized swimming pool. This is effectively a "non-detect" standard given current instrument capabilities.

Furthermore, the designation of PFOA and PFOS as "Hazardous Substances" under CERCLA (Superfund) creates retroactive liability. If your facility discharged these compounds legally in 1990, you can now be held liable for remediation costs if that release is contributing to a plume today. This fundamentally alters the risk profile for mergers and acquisitions (M&A) and Phase I ESAs.

Engineering the Solution: Treatment Train Feasibility

Most industrial Wastewater Treatment Plants (WWTPs) rely on coagulation, flocculation, and biological degradation. These processes do not remove PFAS. In fact, biological treatment can often increase terminal PFAS concentrations by oxidizing precursor compounds (like fluorotelomers) into terminal PFOA/PFOS.

To achieve compliance, facilities must implement tertiary polishing steps. The two dominant technologies are Granular Activated Carbon (GAC) and Single-Pass Ion Exchange (IX) resin.

1. Granular Activated Carbon (GAC)

GAC is the industry workhorse. It works via adsorption, where PFAS molecules adhere to the porous surface of the carbon.

- Pros: Proven technology, lower capital cost (CAPEX), removes co-contaminants like VOCs.

- Cons: "Short chain" PFAS (like PFBS) break through the carbon bed much faster than long chains, requiring frequent changeouts. The operational expenditure (OPEX) is driven entirely by the Empty Bed Contact Time (EBCT), typically requiring 10-20 minutes.

2. Ion Exchange (IX) Resin

IX resins use a charge-based mechanism to capture the negatively charged head of the PFAS molecule.

- Pros: Much smaller footprint (2-3 min EBCT), higher capacity for short-chain compounds.

- Cons: High Sensitivity to TOC and solids. The resin is single-use and must be incinerated or landfilled, creating a long-term waste liability stream.

Strategic Recommendation: The "Source Control" First Approach

Before breaking ground on a $10M GAC plant, the hydrologist's primary duty is Source Control. We have successfully brought clients into compliance simply by auditing their supply chain.

Common hidden sources include:

- Mist Suppressants: Often used in chrome plating tanks (F-53B).

- Mold Release Agents: Used in plastics and rubber manufacturing.

- Level Sensors: Teflon-coated instrumentation leaching into process water.

By identifying and substituting these non-critical PFAS sources, the mass loading to the WWTP can often be reduced by >90%, making the final polishing step significantly smaller and cheaper.

Conclusion

The 2026 compliance deadline is immutable. Validating your discharge characterization using Method 1633 is the critical path item for Q1 2026. Waiting for the NPDES permit renewal letter to arrive is a strategy for consent decrees, not compliance.

About the Author

Zayd Walid

Principal Consultant